2025.09.12

Billions in Market Cap | DatApp × ATW: Empowering Intelligent Manufacturing with Unbreakable Data Security

Share to:

Driven by strategies like Industry 4.0 and "Made in China 2025," China's high-end equipment manufacturing sector has become a core force behind industrial upgrading. The rapid development of fields such as rail transit, aviation equipment, and smart manufacturing not only represents breakthroughs in technological innovation but also carries significant responsibilities for national security and economic development. However, while the digital wave brings efficiency improvements, it also highlights increasingly critical industrial data security challenges—from R&D blueprints and product parameters to supply chain and customer information. The leakage, tampering, or loss of such data can directly threaten corporate competitiveness and even impact the security of national critical infrastructure. Building a secure and reliable data protection system to remain invincible in future competition has become a key issue that high-end equipment manufacturers cannot overlook in their pursuit of high-quality development.

ATW: A Leading Chinese High-End Intelligent Equipment Manufacturer

Wuxi AutoTech Technology Co., Ltd. (hereinafter referred to as "AutoTech"), founded in 2010 and headquartered in the High-Tech Development Zone of Wuxi, Jiangsu Province, employs over 4,000 people. With subsidiaries including AutoTech Intelligence, Songci Electromechanical, AutoTech Xurui, AutoTech Kexin, Liduo Technology, and Wuxi Zhiyuan, AutoTech is a renowned intelligent equipment manufacturer specializing in photovoltaic (PV), lithium battery, and semiconductor fields. In May 2020, the company successfully listed on the Shanghai Stock Exchange's STAR Market under stock code 688516.

Over the past decade, AutoTech has remained at the forefront of the PV industry, committed to technological innovation and R&D. Its products cover all four key segments of the PV industry chain—crystal pulling, silicon wafers, cells, and modules—with core offerings including monocrystalline furnaces, wafer sorters, and multi-busbar stringer machines. The company has successively launched automated equipment such as stringer machines, laser cutting machines, wafer sorters, and light injection annealing furnaces, which have not only helped customers improve product quality and reduce operational costs but also laid a solid foundation for the construction of smart factories.

After establishing a firm foothold in the PV sector, AutoTech began diversifying its portfolio. In 2016, the company entered the lithium battery equipment field, with its self-developed lithium battery module and PACK intelligent production lines, as well as lithium battery appearance sorting equipment, meeting the industry's demand for large-format development. In 2021, AutoTech ventured into semiconductor packaging and testing, with its self-developed aluminum wire bonders breaking the monopoly of Japanese companies and securing bulk orders from clients such as Tongfu Microelectronics and SMIC Integration. In 2023, its semiconductor equipment revenue increased by 365% year-on-year, and its magnetic pull monocrystal furnaces achieved a breakthrough in exports, being sold to a well-known South Korean semiconductor company.

Market-oriented and driven by R&D, AutoTech integrates mechanical, electrical, electronic, optical, machine vision, robotics, and computer technologies to help customers achieve automation, informatization, and intelligence. With a vision of creating smart factories through technology, AutoTech leads the future of intelligent manufacturing. Thanks to its exceptional product performance and attentive after-sales service, AutoTech has earned widespread acclaim in the industry, becoming the preferred equipment supplier for many global module manufacturers. To date, the company has provided stable and reliable equipment, services, and solutions to customers in over 40 countries worldwide.

Building a Data-Driven Smart Factory: Escalating Data Security Challenges

As the digital economy deeply integrates with industrial internet, data has become a key driver of corporate efficiency and intelligent transformation. AutoTech is committed to building data-driven smart factories by leveraging IoT technologies, SAP S/4 HANA, and AWS cloud platforms to enhance digital and intelligent capabilities. By strengthening data accumulation and analysis, the company aims to achieve automated, intelligent, and smart management decision-making in mid- and back-office operations, providing robust support for smart manufacturing and driving the transformation and upgrading of digital smart factories. However, with the continuous expansion of business scale, data volume has exploded, and industry regulations regarding data security have become increasingly stringent. The company’s current data protection measures face multiple challenges:

1. Backup Performance: Rapid business growth has led to massive data volumes. Faced with vast amounts of unstructured data, current backup performance is insufficient, making it difficult to complete backup tasks within the backup window.

2. High RPO Requirements:Core business systems are the foundation of operations and key to ensuring normal company functioning. AutoTech has very high RPO requirements for these systems, allowing no data loss after a disaster.

3. Disaster Recovery:Current data protection methods (e.g., backups, snapshots) have excessively long intervals and cannot restore data to an arbitrary point-in-time before a disaster, failing to meet the need for rapid data recovery.

4. Verification Efficiency:Current data recovery verification involves multiple steps, is time-consuming, labor-intensive, and inefficient. It not only incurs high costs but also struggles to ensure data integrity and validity.

Comprehensive Data Protection: Fortifying Security Defenses in the Digital Era

To address these data security challenges, after extensive comparisons and discussions, AutoTech ultimately chose to partner with DatApp. By deploying DatApp's integrated disaster recovery and backup platform, AutoTech classified and categorized its business systems based on development needs and data characteristics, comprehensively upgrading its data security system to safeguard massive business data and ensure business continuity.Key Implementation Highlights:

1. Real-Time Protection for Core Data, Ensuring "Zero" Data Loss:Disk-based IO-level continuous data protection safeguards core business systems in real-time, enabling restoration to any point-in-time, fully meeting the company's high RPO requirements for core systems. Point-in-time data copies are immediately usable without affecting backup tasks or production systems.

2. Intelligent Protection with "Ultra-Fast" Backup Speeds:Built-in AI auto-search and data reduction engines, combined with efficient deduplication and compression technologies, enable ultra-high-speed backups, reducing the backup window by hundreds or even thousands of times. Changed Block Tracking (CBT) technology accurately identifies and backs up only changed data blocks, minimizing redundant data storage.

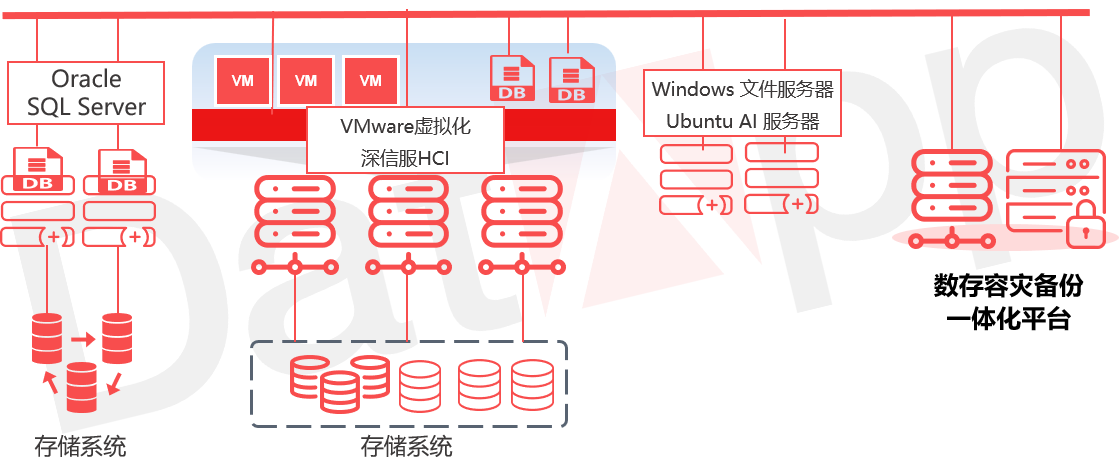

3. Unified Resource Management for Comprehensive Data Protection:The platform offers broad compatibility, supporting existing databases, virtualization platforms, and other environments, providing protection for various data types. It also incorporates traditional scheduled backups, agentless virtualization backup, custom backups, NAS backup, source-side deduplication, remote replication, and forever-incremental protection.

4. Rapid Data Recovery Verification Ensuring Data Validity:Real-time data protection ensures security at any point-in-time. An integrated AI-powered data comparison engine enables fast validation, guaranteeing data integrity, accuracy, and the reliability of disaster recovery equipment, preventing losses from data loss or corruption.

5. Minute-Level Emergency Takeover, Readily Addressing Various Risks: Point-in-time copies can be used for emergency takeover. Whether facing physical hardware failures, OS failures, ransomware attacks, or logical errors, business operations can be restored within minutes, effectively countering risks like accidental deletion, modification, or ransomware—making it a definitive "solution" for such threats.